Innovative approach aims to cut greenhouse gas intensity by 40 percent and secure a low emissions future

It’s an oil sands innovation that’s been in the works for more than two decades.

It’s an oil sands innovation that’s been in the works for more than two decades.

By the end of this year, Imperial Oil will start up the first commercial-scale application of a technology it says will significantly reduce emissions per barrel and position it for low emissions production growth into the future.

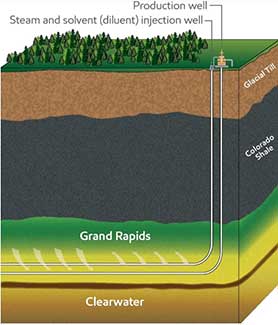

The technology injects light hydrocarbons or “solvents” like diluent, propane or butane deep underground along with steam to melt and mobilize thick bitumen deposits. It’s a bit like adding a thinner to a heavy paint.

The technology is an advancement in steam-assisted gravity drainage (SAGD), which is responsible for nearly half of today’s oil sands production.

Operations at Imperial Oil’s Cold Lake oil sands project. |

| Related Stories |

| Panama Canal crisis signals missed opportunities for Canada’s LNG industry

|

| How sodium batteries will reshape the clean energy future

|

| Backlash forcing Europe to scale back ambitious net zero policies

|

“This is a big deal. This is really good to see, and I hope to see continued momentum,” says Bryan Helfenbaum, associate vice-president of clean energy with Alberta Innovates.

Adding solvents reduces the amount of steam required to mobilize the oil, meaning less energy is used to generate steam per barrel.

“Steam is directly correlated with greenhouse gas emissions, so the emissions intensity of the oil coming out of those wells or well pads is reduced,” Helfenbaum says.

At the end of 2022, Imperial announced it would accelerate its timeline to get the first 15,000 barrel-per-day phase operating by the end of this year. The project is now nearing completion, the company announced with its third quarter results.

Schematic of a solvent-assisted SAGD well pair.

Image courtesy Imperial Oil

“This will be the first solvent assisted SAGD in industry,” senior vice-president Simon Younger told Imperial’s investor day earlier this year.

“It will deliver a 40 percent reduction in greenhouse gas intensity relative to our cyclic steam stimulation process, which is our legacy technology at Cold Lake.”

Imperial’s Cold Lake project is one of the oil sands industry’s longest-running operations. It started up in 1975 and underwent phased expansions over the subsequent decades. It has produced more than one billion barrels of oil.

The company was one of the first to pilot solvent-assisted production, Helfenbaum says. This includes a “highly successful” demonstration between 2009 and 2013, according to a report by Alberta’s Innovative Energy Technologies Program.

Momentum to develop the large-scale solvent assisted SAGD project now is likely driven in part by Imperial’s membership in the Pathways Alliance, Helfenbaum says.

The partnership of six companies representing 95 percent of oil sands production aims to apply technology to reach net zero emissions from operations by 2050. Pathways says solvent assisted SAGD is a priority emerging technology.

“Pathways’ carbon capture and storage project tends to get most of the headlines these days, but also on that list of opportunities to get to net zero by 2050 is solvents,” Helfenbaum says.

Imperial CEO Brad Corson says the company “has a whole pipeline” of solvent deployment potential at Cold Lake.

“We’re continuing to explore future generations of opportunities that will allow us to not only grow production but do that in a lower cost way and also, quite importantly, with lower emissions intensity,” he says.

Deborah Jaremko is director of content for the Canadian Energy Centre, a Troy Media Editorial Content Provider Partner.

For interview requests, click here.

The opinions expressed by our columnists and contributors are theirs alone and do not inherently or expressly reflect the views of our publication.

© Troy Media

Troy Media is an editorial content provider to media outlets and its own hosted community news outlets across Canada.